在镁转印箱外壳中穿

格雷格·纳米德

Transfer cases with magnesium housings include but are not limited to: the Ford/BorgWarner4405.和4411, and the 1999 and newer GM/New Venture 136, 149, 236, 246, 261 and 263 models. The type of magnesium alloy dealt with here is AZ91D, which is commonly used in these and other automotive applications. Wear in the Ford/BorgWarner (BW), typically causes engagement issues and rear seal leaks, while the GM/New Venture (NV) units show up with pinhole leaks in the housing and a loss of fluid. Magnesium transfer cases can be identified by the letters “Mg” inside a triangle cast on the outside of the housing.

First, a little background about magnesium. It is the eighth most abundant element in the earth's crust and the lightest structural material. It is 75% lighter than steel and 33% lighter than aluminum. Its light weight and reasonable strength make it a popular material for automotive engineers trying to trim weight from vehicles. In the BorgWarner transfer case application, 10 pounds were saved by using magnesium vs. aluminum. A common perception is that magnesium corrodes easily. However, the bare material actually rates better at corrosion resistance than aluminum. Where magnesium has a problem is when it is close to other metals and salt. The result is “galvanic” corrosion, which can rapidly corrode magnesium.

If you have worked on many of these units from areas with salt-treated roads, you’ve surely seen the external case material corroded away. To deal with galvanic corrosion, magnesium transfer cases use separators and special coatings on bolts, and even have special contours so that road debris (salt) is less likely to compact into small spaces. One other interesting fact about magnesium: it is a metal that can burn. When burning, it does not require oxygen to support combustion and water can actually feed the reaction. Class D fire extinguishers and smothering with sand are recommended to put out fires, so before machining or welding, take necessary precautions and be aware of what you are dealing with.

What about the wear? Both the BW and NV housings are notorious for fretting-type wear when internal moving parts contact the magnesium. In addition to sliding movement, this also includes parts that do not need to move but, due to normal clearances and vibrations, have some amount of relative movement between the part and the magnesium. Bearing races, shafts, retaining rings, pump locating arms and even metal “anti-wear” inserts all wear away the magnesium to some degree. Both BorgWarner and New Venture have other similar transfer cases made with aluminum housings. Wear on these aluminum versions is just not an issue like it is with the magnesium versions. The simple answer is that the magnesium versions wear more because magnesium is not as hard as aluminum.

这是通过在材料加工技术杂志中出现的研究证明的。为了研究如何涉及转移壳体磨损,我将铝和镁和福特两者的铝和镁转印箱壳体的样品收集。将样品在室温下测试硬度,以200度华氏度。Figure 1仅供参考,是使用普通罗克韦尔B&C硬度尺度的材料硬度的一般指南。

Figure 2显示实际转移壳体壳体的硬度测试结果。值得注意的是,不仅镁比铝更柔软,而且在200°F的工作温度下,差异更加戏剧性。与铝相比,罗克韦尔B秤上的镁在低于(更柔和)的40.1点!除了硬度测试外,还对镁镁进行了加速磨损试验。结果表明,比镁更硬的材料将有助于镁壳体的磨料/微动磨损。

我的结论是,在可比应用中,镁在铝中比铝更柔软,并且在车辆工作温度下甚至更大。Due to the relative softness of the AZ91D cast magnesium, any material that is harder than the magnesium (i.e. steel or aluminum) is abrasive or has sharp edges that will wear into the magnesium housings and create the type of wear we typically see in these units. Repair options should focus on eliminating the movement between harder/abrasive components and the magnesium housing (which is not always practical), or isolating the moving part with a non-abrasive, low-friction material that is softer than the magnesium itself.

Related Parts

需要

Recommended

新过程230和240系列

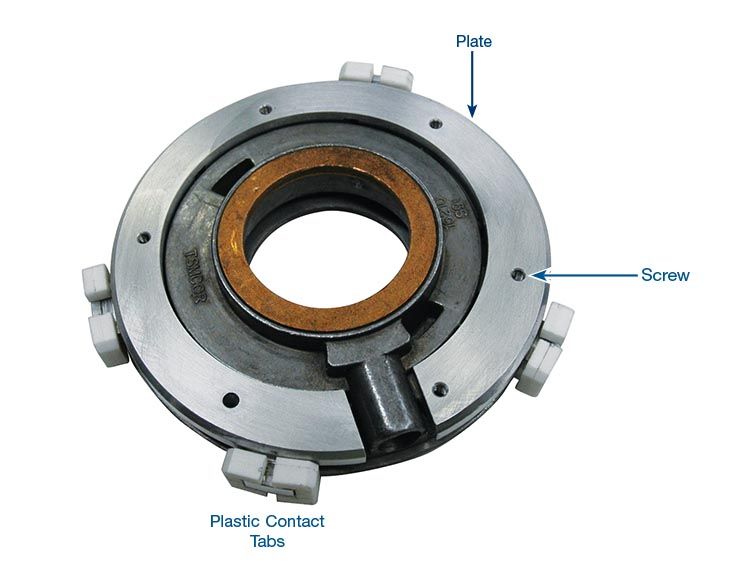

转移盒泵板套件100246-02K

NP 136,149,236,246,261,263

-

Helps cure:

- Rear housing wear

- Damaged transfer cases must be scrapped

- 后转印箱外壳中的针孔油泄漏

虽然Sonnax尽一切努力确保在出版时确保技术文章的准确性,但我们对不准确或可能过时或过时的信息不承担任何责任。