2017年8月28日

Sonnax回答了对编织碳摩擦环的最大问题

自动的里程碑事件传播aftermarket occurred in late 2015 when Sonnax became the first company to offer authentic, OE woven carbon friction material to torque converter rebuilders. Ever since GM introduced their EC3 converter clutch strategy in the 1990s, the aftermarket had struggled to find a material that would both slip in a controlled manner and provide good drivability and long life. Without access to the OE material, the options were limited. Rebuilders had to reuse qualified core components or switch to an alternate aftermarket material they hoped might be good enough to meet the demands of a continuous-slip application. As they quickly discovered (often the hard way), some friction materials were better than others at meeting the demands of these slipping applications, but nothing beat the performance and reliability of woven carbon. It’s so good at what it does that today it’s used in a variety of GM and Ford applications — yes, Ford! Units Ford co-developed with GM, such as the 6F35 and the 6F50, also rely on woven carbon for use of TCC friction material.

当Sonnax释放编织碳的转矩转换器售后市场时,我们的客户的反应是立即的:你喜欢它乐动BBIN彩票!材料是耐用的,有助于消除滑动码,容易粘合,令人惊讶的价格。对于最初使用它的应用,Sonnax编织碳使转矩变换器和传输重建者具有高寿命和巨大的驾驶能力的高度信心。乐动BBIN彩票

It’s great you can confidently tell your customers that you have the EXACT OE material, but there’s a good chance some basic questions remain, particularly these two: “Can I get a solid ring instead of a segmented ring?” and “I have units where I need to turn down the cover or the piston. Can I get your OE woven material, except thicker?” To fully understand the issues and the answers, let’s do a little analysis. First, let’s tackle the segmented ring request. Then we can look at the variables associated with designing and manufacturing a thicker material.

问:我可以得到一个固体环而不是分段戒指吗?

答:不......但你真的不想要一个。

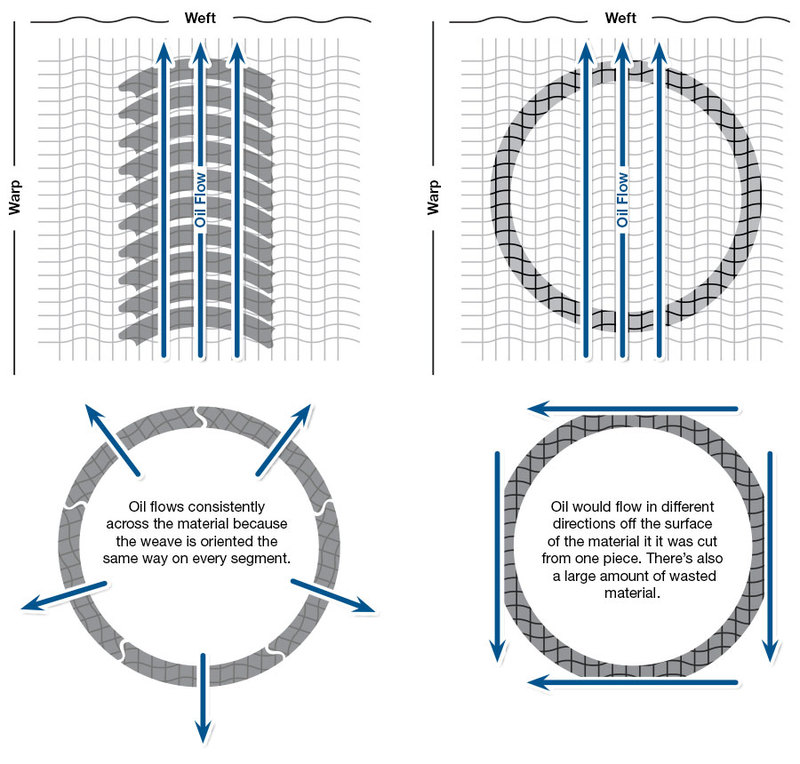

In all OE applications, the woven carbon friction rings are built from five separate segments. There are two fundamental reasons why making a full ring is not feasible for the aftermarket: performance and cost.

The higher cost aspect of a full ring is pretty obvious: If you cut solid rings from a piece of fabric, the center of the ring would be wasted material. Everyone understands that wasted material equates to higher costs. What’s not so easy to grasp is why a woven carbon solid (or full) ring would perform differently than a segmented ring. To better understand the concept, you have to remember that this material is woven fabric, not a wet-laid paper like traditional friction materials.

看着编织碳的结构,在栅格上进行编织的纤维。在外行的条款中,一些纤维是垂直的,有些纤维是水平的。这些光纤以自定义模式交织在一起以创建指定的材料。

在纺织品中,垂直纤维被称为“经线”和水平纤维作为“纬纱”。在这种碳织物的设计中,经纱和纬线不同。经纱和纬纱的具体模式会影响摩擦环的面部的流动,是材料提供的滑动速率的因素。因此,沿着经线轴的流动(和滑动率)与沿纬线轴的流量不同。如果由这种织物制成完整的摩擦环,则在环的面上的经纱和纬纱图案不会匹配,导致截然不同的流量和滑移率。这种不一致性会导致性能和持久性问题,与您想要建立在转换器中的完全相反。

问:我有我需要拒绝盖子或活塞的单位。除了更厚的情况外,我可以获得你的OE编织材料吗?

A: No… but you really wouldn’t want it thicker.

编织碳材料非常薄于开始;粘接和完全压缩后,它只有.020“。客户经常要求厚度的厚度碳,但是,由于它们在车床转弯和活塞之后,所以.020”材料doesn’t get them the required overall height or clutch release clearance. We again have to go back to the source of woven carbon — the OEM — to understand why a thicker material is not available.

When GM engineered this material, it was created to survive in an environment of continuous slippage. To get the material to live up to the task, GM performed countless tests and invested millions of dollars to develop a friction product that would slip at the desired rate, take the added heat, drive well and be very durable. Once the specifications for the material were set, dedicated production looms were built to weave large quantities of this proprietary material. Fast forward to today and those dedicated production looms are still cranking out rolls of fabric for use in GM and Ford converters. The woven carbon friction rings offered by Sonnax are made from the same OE fabric that comes off those same looms.

改变编织碳是多大的碳。一方面,创造更厚的材料将需要广泛的研发努力。当然,较厚的织物可以从经线和纬纱中使用的较厚的纤维编织,但这对滑移速率,流动特性,耐用性或驾驶能力是什么?如果没有新的研发努力支持较厚的材料,就没有确定产品的性能和寿命。另一个重要因素是,与大OE容积相比,售后市场使用微量编织碳。设立织机以编织更厚的材料需要大的资本支出,需要计算的薪酬。A.040的假设价格“售后可售的仅编织的碳摩擦环需要是天文高的,以便开发更厚的材料以产生任何经济意义。

Q: OK, I DON’T want a thicker ring, but I still need to repair converters that originally came with woven carbon friction material. What do I do?

答:你打电话给Sonnax!

芯部件通常损坏,并且前盖或离合器活塞(或两者)需要车床转动。非俘虏离合器,300mm版本的6L80 / 90是一个经典的例子。由于Rebuilders知道,在损害盖子和活塞的完整性之前,可以将材料除去多少材料,并且通常这些6L80 / 90s损坏到它们无法挽救的程度。在这些情况下,商店可以通过用Sonnax的新的,更强大的部件更换OE冲压盖和活塞来重建这些单位(并使用编织碳!) - 请您的销售代表GM-CC-13封面和新的GM-DA-17p活塞。将这些重型伪造的组件纳入您的构建中,使得较好的升级,不再需要更多时间来组装股票。

In applications where new covers or pistons are not available and your inventory of core components requires salvaging covers and pistons, BorgWarner HTE and HTS friction material from Sonnax is a great alternative. While it’s a paper-based friction ring instead of woven carbon, it’s proven that it can survive in continuous slip applications. If you need to make up for the material lost from the turning and facing of core components, the BorgWarner HTE and HTS materials come in thicknesses of .045” and .066”.

底线:Sonnax的编织碳摩擦环旨在在价值和性能方面提供绝对的最佳状态。无论您想要对通用汽车和福特连续滑动应用的摩擦材料还是需要一种材料,这些材料将允许您弥补从核心打捞业务中的组件零件所面对的钢,Sonnax您已经覆盖!

Steve Jaussaud is the vice president of product line management and a member of the SonnaxTASC Force(技术汽车专业委员会),一批认可的行业技术专家,传输Rebuilders和Sonnax Industries,Inc。技术人员。

了解更多

Related Parts

虽然Sonnax尽一切努力确保在出版时确保技术文章的准确性,但我们对不准确或可能过时或过时的信息不承担任何责任。