Transmissions & Oversized Tires: How Changing Gear Ratios Helps Prevent Drivetrain Damage

杰森劳肖尔

Inst alling bigger tires on trucks is about as American as baseball, country music and apple pie. Unfortunately, big tires also go hand-in-hand with something less enjoyable: transmission failure. You can guard against problems and better troubleshoot chronic failures by knowing the unintended consequences of oversized tires on the tranny, especially the role gear ratios play in managing torque as it travels through the drivetrain.

alling bigger tires on trucks is about as American as baseball, country music and apple pie. Unfortunately, big tires also go hand-in-hand with something less enjoyable: transmission failure. You can guard against problems and better troubleshoot chronic failures by knowing the unintended consequences of oversized tires on the tranny, especially the role gear ratios play in managing torque as it travels through the drivetrain.

While big tires are a popular vehicle mod found throughout the United States, some would argue that this trend was actually inspired by the work of a French engineer in the early 20th century. Adolphe Kegresse installed an off-road track system onto various Rolls-Royce cars and Packard trucks and later developed it for use in World War II when vehicles needed to reach remote locations. After the war, private contractors and companies started utilizing the concept of adding more ground clearance to access remote parts of the country with their vehicles. The difference in their method was that they modified the suspension to raise the vehicle and put on larger diameter tires. This was mostly done to large commercial work trucks at this time.

Fast forward to the 1970’s, and you’ll find this is when the lifted big tire craze took off. “Bigfoot,” arguably the first monster truck, was created by Bob Chandler during this time period. Once monster truck events were televised and the trend caught on, regular folks wanted to replicate this cool look and explore areas they could not access with stock tires. To accommodate larger tires, companies started making lift kits, and automotive manufacturers began offering special, off-road versions of their popular pickups. The tough look of big knobby tires and the ability to go where others can’t did come with some downfalls, however. Now that we know how the trend started, let’s look at some of the negative aspects of oversized tires.

自然升级到更大的轮胎外直径increases the circumference, the distance around the outside of the tire. The circumference is used to calculate your speed, so any deviation from the factory tire size will affect this. This problem is minimal in newer vehicles that use an electronic speed sensor and can be corrected with programmable tuners. In older vehicles that rely on a cable- and gear-driven speedometer, though, adapters, calibration boxes or speedometer gear changes are necessary.

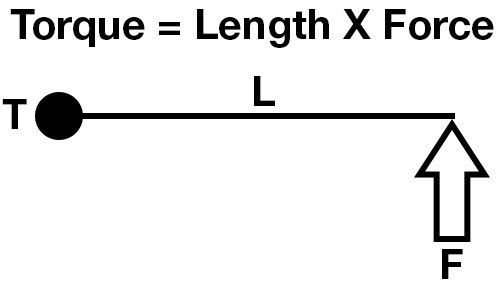

The biggest issue with installing taller tires is the increased strain on the drivetrain. To get a better look at this consequence, we can go back to physics class — I’ll even give you some homework. For this example, we will use this torque formula:

Increasing the length (L) of the lever arm increases the torque (T) applied. This theory is put to test every time you reach for a longer breaker bar for that stubborn, rusted bolt.

然而,这种理论在增加轮胎的半径时效果,因为它现在需要从传动系列的更大扭矩转动那个较大的轮胎。体育投注在线这通常对发动机部件本身具有大大负面影响,尽管现在需要发动机更加努力地保持与以前相同的速度。另一方面,传动部件尤其是离合器和频带,采取滥用的冲击。离合器和频段将开始产生过多的热量,因为它们在较高的恒定应力下运行。过热循环将导致摩擦表面开始滑动,并且在该点处,传输需要大修。如果失败的核心问题未得到解决 - 增加轮胎大小 - 问题将一次又一次地发生。

那么你如何安全地运行那些没有股票的车辆的那些大,35英寸轮胎?

Re-gear.

所有后轮驱动器(RWD)车辆在后轴外壳内部具有一组齿轮,称为环形和小齿轮齿轮,可确定最终齿轮比。四轮驱动器(4WD)车辆在前轴外壳中设有一组。

小齿轮齿的牙齿显着较小,并且将比环形齿轮旋转多。齿轮比将标记为3.42:1,或3.42转的小齿轮和驱动轴的转速,用于轴轴的一个旋转。如果您要订购一辆新卡车,您可以从少量选择的可用齿轮比要求。这些齿轮比是由工程师计算的,以最大化扭矩,加速,发动机RPM在公路速度和最终的气体里程,同时考虑到已知的轮胎直径。这些齿轮组可以由不同的售后市场或原始设备齿轮组的专业人员改变。改变最终的齿轮比将纠正由轮胎造成的动力传动系统缺陷。显然,更昂贵且难以修改4WD驱动齿轮比而不是RWD,因为有两组要改变。

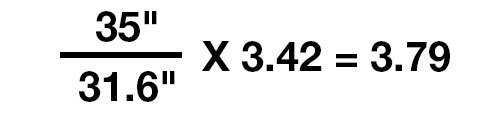

To find your new optimal gear ratio, you can use this formula:

让我们看看该公式如何适用于2017年GMC塞拉Z71,该Z71具有265 / 65-18(31.6“Dia。)轮胎。假设3.42:1齿轮比,我们可以计算新的齿轮比:

没有w that we have restored the vehicle’s driving characteristics and power, it’s time to get out and enjoy the outdoors safely and responsibly. A very popular hobby called Overlanding is gaining popularity where people outfit their trucks and SUV’s with tents, beds, cooking implements and other amenities and drive on unimproved roads out in the country. Of course there will also always be the 4WD trucks fitted with 35” tires that never once see a dirt road. Those vehicles especially need re-gearing because of how often they are driven at highway speeds.

Jason Larchelle是Sonnax产品支持代表。他是一个成员Sonnax Tasc力量(Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

Related Units

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.