January 19, 2013

Valve Body Qualification

鲍勃沃纳克

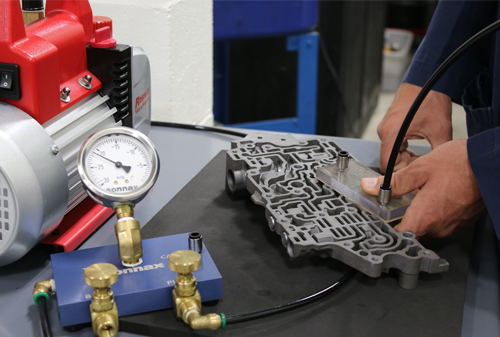

考虑到传输的维修费用高,the value of efficient diagnosis has never been higher. Vacuum testing has become a trusted method for identifying valve body problems and verifying repairs. Technicians can easily expand this diagnostic tool to other areas when they have a good understanding of how it works and the leakage-prone transmission components to target. (Watch the video at the end of this article for a demo of 4L80-E overrun clutch vacuum testing in action!)

阀体真空测试的起源

由于越来越复杂的部件,尤其是用于测试阀体而导致的传输测试方法被迫发展和变化。很多年前,在Sonnax,我们认识到在更新的轻质阀体组件中准确诊断佩戴存在挑战。阀门孔和阀芯上的磨损产生了换档控制问题。这些问题也取决于油是否厚(冷)或薄(热)。常规测试当时是Wiggle测试,湿空气测试,手电筒测试和钻孔测试。这些早期的实践没有给出可靠的结果,更薄,更轻薄的液体。技术人员需要更准确的测试来获得一致和可重复的结果。有能力测量液压控制单元内的磨损并能够在修理后重新测试以确认结果是至关重要的。

Vacuum testing valve bodies was developed to meet this challenge, as it allows the technician to assign a quantifiable value that corresponded to leaks in the valve bore area. This method was already used by engine builders to test for leaking valves, valve seats and guides. Applying vacuum testing to valve bodies provided a cost-effective, repeatable approach and gave very precise answers with documented numbers.

|

| Valve Body Vacuum Testing |

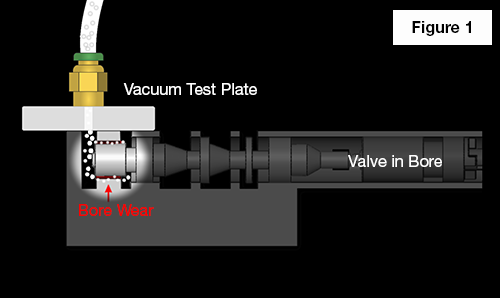

它是如何工作的:电动真空泵用于通过铸孔和阀芯的外径之间的空间拉动恒定真空(图1)。然后可以在校准量表上读取阀门到孔隙间隙的真空值(图2)。This new method of testing took the guesswork out of determining wear and was found to be accurate for both lightly worn and high-mileage castings, old and new.

| 图1 - 阀体真空测试 |

|---|

|

| 图2– Vacuum Test Results |

|---|

|

Sonnax理解这项测试方法可能是多么有价值,以便在路上教授它的方式是多么简单。通过Sonnax Roadshow,技术人员学习了如何测试和诊断阀体,并且在需要时进行维修。他们现在可以验证是否需要根据可测量的结果进行维修或更换。看看Sonnax Roadshowto view some videos that will help get started with testing valve bodies.

是时候超越阀门

The same vacuum testing approach used to test valve bodies can also be used on other transmission components and sealed containment areas such as holding brakes and clutch drums. Modern transmissions are much more prone to leaks in these areas than older units. Type F and Dex fluids, the first fluids used in automatic transmissions, would break down and create a varnish build up. This varnish actually sealed leaks in the hydraulic systems and allowed for looser machining tolerances during manufacturing. Unfortunately, the varnish also filled the pores of friction materials with thick pasty fluid that could not be squeezed out when the clutch pack was applied, causing heat and chatters against steel plates or drums.

Modern transmission fluids do not create a large amount of varnish, therefore do not seal leaks like the older fluids did as they broke down. Leaks within the transmission create heat, which causes expansions to increase, which in turn creates bigger leaks. These leaks can be responsible for lifting checkballs in containment areas, exhausting lube oil and preventing it to reach destinations and ultimately causing gear, band and clutch failures. Here are some areas that can cause expensive repeat failures that could be diagnosed with vacuum testing:

还有很多!

让我们来看看一些简单的真空测试,可以将特定值放在装配中泄漏 - 泄漏传统的空中测试无法找到。这些真空测试以及适当的空气测试,有助于防止卷重。我所知的一个重要课程是测试中的目标不是将责任归咎于一个组件,而是要排除你所知道的不是导致问题更容易找到导致失败的原因。

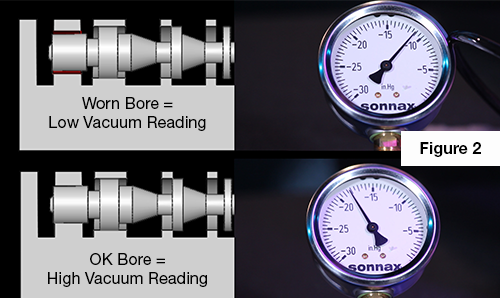

你需要记住的只是“石油=油。”在4L80-E(基于故障组件)上的REBUILD期间,指示溢出离合器电源的馈电电路可能是一个问题,并确认它可以变得重要(图3.)。The failure with this unit that caused the need for repair was the “overrun clutch was burnt and the overdrive roller clutch had failed.” These two failures created this no Forward and no Reverse movement.

| 图3 - 潜在的泄漏区域 |

|---|

|

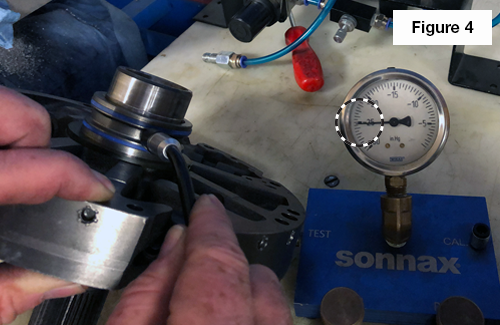

第一次测试检查泄漏,用于阻挡从芯钻和定子管压入盖子中的通道的芯钻头。用手指插上顶部和底部铸造钻头/油输送通道,将橡胶尖端的试管插入定子管孔(Figure 4)。测量仪的结果必须在真空测试规(如果25英寸)上显示零泄漏,在校准时是密封号码)。

| Figure 4 – Core Drill Plug & Stator Tube Test |

|---|

|

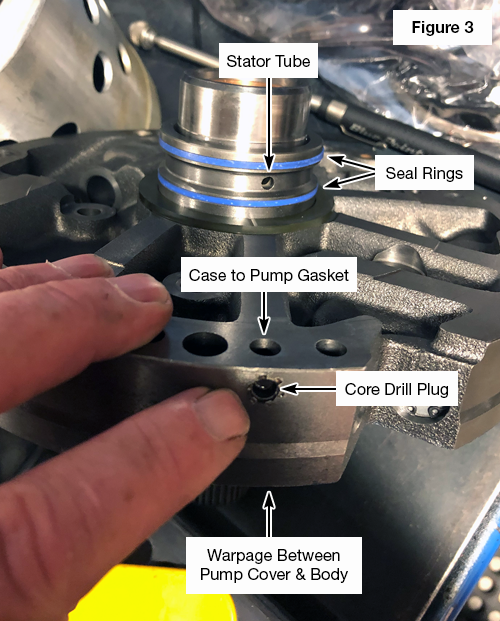

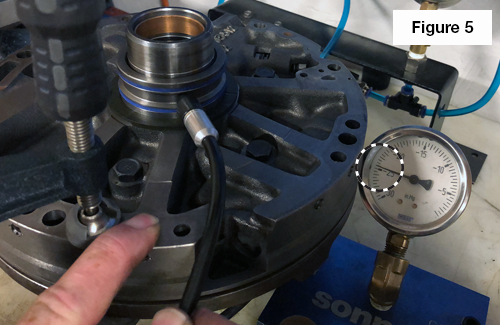

由于泵中的翘曲作为组装到主体的翘曲,泄漏也可能发生,因此第二次测试通过组装泵(扭转在一起)。组装时,安装夹具以确保外边缘紧密。插头馈电孔用手指和真空测试在密封环之间的定子管孔,带橡胶尖端的试管。测试结果不应落在量规上的1英寸真空。如果它掉落的那样,泵应浮出水面以防止失败。如图所示图5.,盖上盖子的原始测试是25英镑,现在,用螺栓固定在一起,我们发现只有24个in-hg的结果泄漏。这没关系,因为它不超过1“的区别。任何大于2”,你应该尝试隔离泄漏的位置。这可以包括泵和盖板的两侧。

| 图5.– Warpage Test |

|---|

|

我们将在未来的文章中继续写作和说明不同的测试程序,因此请保持睁眼。如果您正在遇到任何测试和电路,请通过联系我们来告知我们乐动体育app 。直到那时,保持那些变速器健康。

Randall Schroeder是一个Sonnax技术销售和培训专家。他是Sonnax的成员Tasc力量(技术汽车专业委员会),一批认可的行业技术专家,传输重建者和Sonnax技术人员。

January 19, 2013

鲍勃沃纳克

2011年1月22日

2015年1月05日

2015年1月05日

2015年1月05日

2017年9月12日

兰德尔施罗德

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.