Six Ways from Sunday: Diagnosing ZF6 & Ford 6R60/80 TC-Related Drivability Concerns

鲍勃沃纳克

什么是wk?

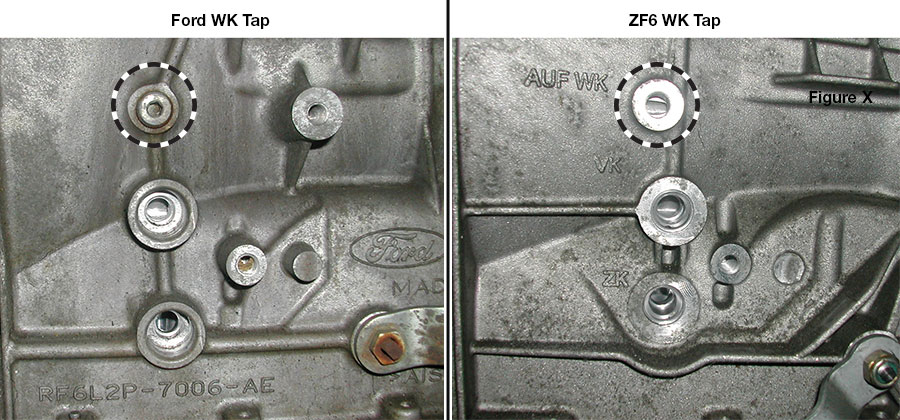

| Figure 1 |

|---|

|

Accessing WK

正常的WK.

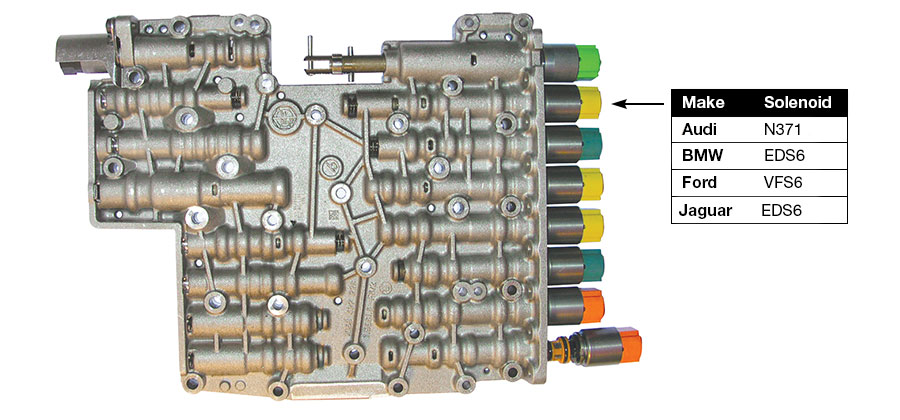

| Figure 2 |

|---|

|

Abnormal WK

- TC Slip

- 部分释放

- TCC/Solenoid/Ratio Codes

- Harsh Shifts

- Flare Shifts

- Rough Idle in Reverse

The Root Cause

A Ford Note

没有机电图交换允许

Bring It on Home

相关单位

相关零件

Required

推荐的

6R100,6R60,6R75,6R80 (2009-2014),6R80 (2015-Later),ZF.6HP19,ZF.6HP21,ZF.6HP26,ZF.6HP28,ZF6HP32.,ZF6HP34.

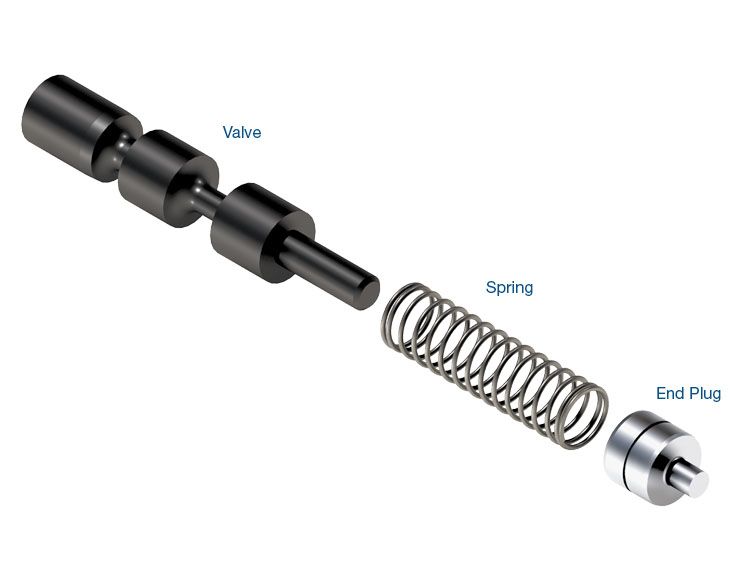

超大的d Converter Release Regulator Valve Kit95740-05K

OE valve name: WK-V

-

Helps cure:

- Excess TCC slip RPM & related codes

- 苛刻的TCC适用和发布

- 低TCC释放压力

- 反向粗糙闲置

- Harsh downshifts

- Flare shifts

- Overheated converter

Required

推荐的

6R100,6R60,6R75,6R80 (2009-2014),6R80 (2015-Later),ZF.6HP19,ZF.6HP26,ZF6HP32.

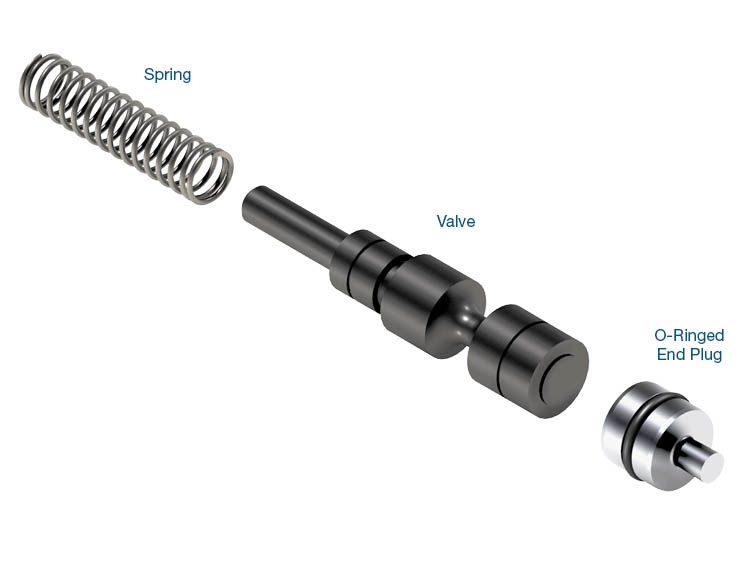

超大的d Lubrication Control Valve Kit95740-11K

OE valve name: SCHM-V

-

Helps cure:

- Planetary failure

- Bushing failure

- Lube failures

- 过热

- 低转换器压力

- 凹凸班次

- Flare shifts

- 反向粗糙闲置

- TCC apply & release concerns

Required

推荐的

ZF.6HP21,ZF.6HP28,ZF6HP34.

超大的d Lubrication Control Valve Kit95740-71K

ZF.valve name:SCHM-V

-

Helps cure:

- Bearing failure

- Bushing failure

- Planetary failure

- Lube failures

- 低转换器压力

- 过热

- TCC codes & concerns

- 反向粗糙闲置

Required

推荐的

6R100,6R60,6R75,6R80 (2009-2014),6R80 (2015-Later),ZF.6HP19,ZF.6HP26,ZF6HP32.

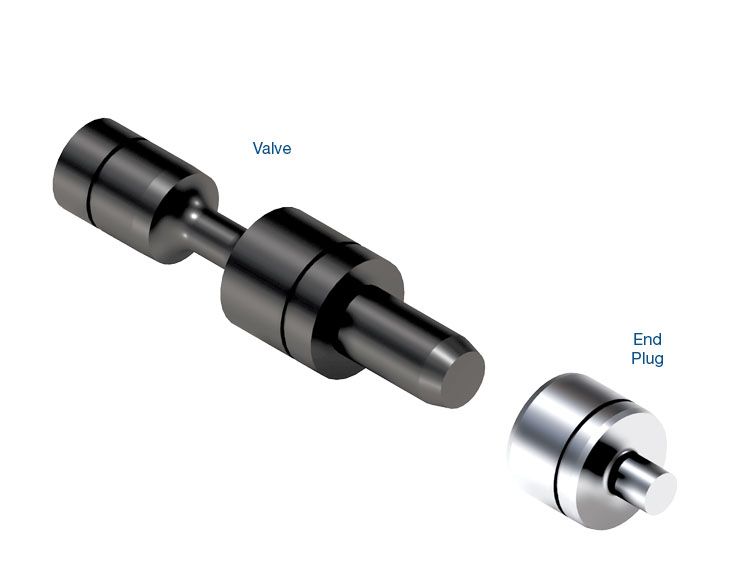

超大的d Bypass Clutch Control Valve Kit95740-13K

OE valve name: WD-V

-

Helps cure:

- TCC codes

- Excess TCC slip

- Cycling RPM

- 低TCC释放压力

- Flare shifts

- Harsh shifts

- 反向粗糙闲置

- Overheated converter

Required

推荐的

ZF.6HP21,ZF.6HP28,ZF6HP34.

超大的d Bypass Clutch Control Valve Kit95740-73K

ZF.valve name:WD-V.

-

Helps cure:

- TCC codes

- Excess TCC slip RPM & related codes

- 低转换器压力

- Overheated converter

- Flare shifts

- Harsh shifts

- 反向粗糙闲置

Required

推荐的

6R100,6R60,6R75,6R80 (2009-2014),6R80 (2015-Later),ZF.6HP19,ZF.6HP26,ZF6HP32.

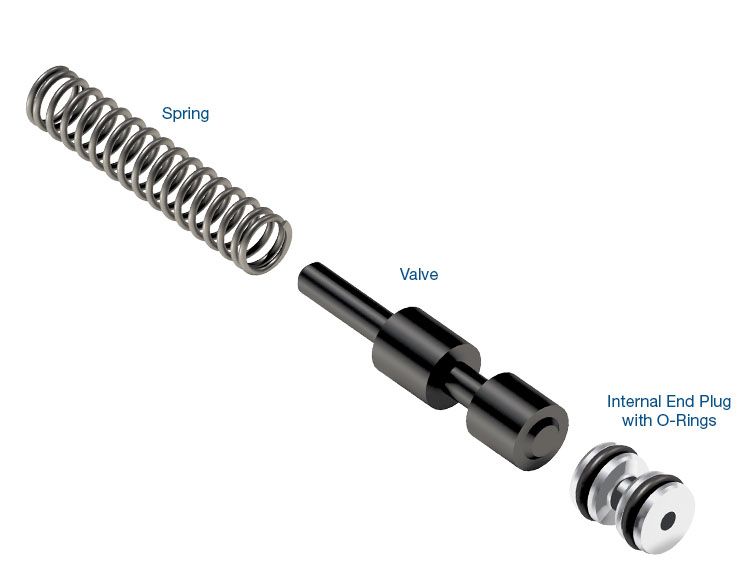

超大型电磁调压器阀门套件95740-17K

ZF.valve name:Dr.Re-V.

-

Helps cure:

- Flare shifts

- 中立班次

- Harsh upshifts

- Harsh downshifts

- Gear ratio codes

- Solenoid performance codes

- Delayed Forward

- 延迟反向

- Wrong gear starts

- TCC slip

Required

推荐的

ZF.6HP21,ZF.6HP28,ZF6HP34.

超大型电磁调压器阀门套件95740-64K.

ZF.valve name:Dr.Re-V.

-

Helps cure:

- Delayed engagement

- Flare shifts

- Harsh downshifts

- 中立班次

- 高线压力

- Harsh upshifts

- Wrong gear starts

- Gear ratio & solenoid codes

- TCC slip

Required

推荐的

ZF.6HP19,ZF.6HP26,ZF6HP32.

超大的d Pressure Regulator Valve Kit95740-78K

单位符合053年分离器板。

OE valve name: SYS.DR-V

-

Helps cure:

- Broken parts due to excessive line pressure

- Erratic line pressure

- Harsh shifts

- 高线压力

- 限制转换器/润滑油流量

- 软班次

- Flare shifts

- TCC slip

Required

推荐的

6R60,6R75,6R80 (2009-2014),ZF.6HP19,ZF.6HP26,ZF6HP32.

超大的d Pressure Regulator Valve Kit95740-01K

适合6 r80 ' 09 - 14所示。不能用于单位that have a 053 separator plate.

OE valve name: SYS.DR-V

-

Helps cure:

- 差塑质量不佳

- Flare shifts

- Harsh shifts

- Erratic line pressure

- Slips in Forward & Reverse

- 延迟反向

- 没有反向

- TCC slip

Required

推荐的

ZF.6HP21,ZF.6HP28,ZF6HP34.

超大的d Pressure Regulator Valve Kit95740-69K

ZF.valve name:sys.dr-V.

-

Helps cure:

- 差塑质量不佳

- 低线压力

- Flare shifts

- 高线压力

- Harsh shifts

- Burnt converter

- 延迟反向

- 没有反向

- TCC slip

Required

推荐的

,6R80 (2009-2014),6R80 (2015-Later),ZF.6HP19,ZF.6HP26,ZF.6HP28

Input/Output Shaft Bushing95030-05.

Fits units with .669" (16.98mm) dia. shaft journals only.

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:0.788”

- Shaft Dia.:0.669"

- 宽度:0.393"

-

Helps cure:

- Bushing wear

- Bushing failure

- Ratio codes

- B Clutch burned

Required

推荐的

Required

推荐的

Required

推荐的

Required

推荐的

Required

推荐的

ZF.6HP26,ZF.6HP28

Bushing Kit95030-26K.

Fits units with input shaft bushing journal diameters of 1.022" (25.97mm) & 1.180" (29.96mm).

- Bushing Style:精确

- Material:Bimetal

-

Helps cure:

- 电子离合器被烧掉了

- B Clutch burned

- Gear ratio & solenoid codes

- Bushing wear

- Bushing failure

Required

推荐的

ZF.6HP26,ZF.6HP28

Sun Gear Shaft Bushing95030-06A

Fits units with .991" (25.17mm) shafts only.

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:1.103"

- 宽度:0.394"

- Shaft Dia.:0.991"

-

Helps cure:

- B Clutch burned

- Bushing wear

- Bushing failure

- Ratio codes

Required

推荐的

ZF.6HP19,ZF.6HP21

Sun Gear Shaft Bushing95030-06B

仅适用于.833“(21.15mm)轴的单位。

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:0.953"

- 宽度:0.394"

- Shaft Dia.:0.833“

-

Helps cure:

- B Clutch burned

- Bushing wear

- Bushing failure

- Ratio codes

Required

推荐的

ZF.6HP19,ZF.6HP21

Sun Gear Shaft Bushing95030-06D

Fits units with .904" (22.98mm) shafts only.

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:1.024"

- Shaft Dia.:0.904"

- 宽度:0.394"

-

Helps cure:

- B Clutch burned

- Bushing wear

- Bushing failure

- Ratio codes

Required

推荐的

ZF.6HP19,ZF.6HP21

"B" Clutch Bushing95030-07A

仅适用于1.219“(30.97mm)轴的单位。

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:1.339“

- Shaft Dia.:1.219“

- 宽度:0.394"

-

Helps cure:

- Bushing wear

- Bushing failure

- B Clutch burned

- Ratio codes

Required

推荐的

ZF.6HP19,ZF.6HP21

Sun Gear Shaft Bushing95030-06C

Fits units with .853" (21.68mm) shafts only.

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:0.973"

- Shaft Dia.:0.853“

- 宽度:0.394"

-

Helps cure:

- B Clutch burned

- Bushing wear

- Bushing failure

- Ratio codes

Required

推荐的

ZF.6HP19,ZF.6HP21

"B" Clutch Bushing95030-07B.

Fits units with 1.396" (35.47mm) shafts only.

- Bushing Style:精确

- Material:Bimetal

- 房屋钻孔:1.516"

- Shaft Dia.:1.396“

- 宽度:0.394"

-

Helps cure:

- Bushing wear

- Bushing failure

- B Clutch burned

- Ratio codes

Required

推荐的

ZF.6HP19,ZF.6HP21

Bushing Kit95030-19K

- Bushing Style:精确

- Material:Bimetal

-

Helps cure:

- 电子离合器被烧掉了

- B Clutch burned

- Gear ratio & solenoid codes

- Bushing wear

- Bushing failure

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.